Flexible Flood Membrane Systems

Among the easiest, lightest a fastest to deploy, we believe that FloodBarrier’s Flexible membrane systems are the best in the world. From a single doorway to a multi-lane tunnel entrance, our flexible systems are ridiculously strong, amazingly watertight and very easy to deploy.

FloodBarrier’s Flexible Flood Membrane Systems

Construction

Design factors for anticipated dynamic loading drive the construction element requirements of the Flexible Curtain Family of products. There are extreme heavy duty, heavy duty and medium duty designs of the structural components of the flexible curtain systems. FloodBarrier utilizes UHMWPE and/or ARAMID, Aluminum and / or Stainless Steel in the structural design elements.

All textile structural material utilized in the system is woven to the specific design requirements of the product.

15x stronger than steel

UHMWPE products are hydrophobic, providing a flood barrier system which does not absorb moisture or deteriorate in water.

Its naturally buoyancy provides engineers an ability to design

using a wider palette of options. UHMWPE products exhibit no corrosion, superior chemical resistance, increased abrasion resistance and excellent flex fatigue. This results in a flood barrier

system that lasts longer with reduced maintenance costs.

Deployment times for individual openings vary according to the size and design of the barrier. FloodBarrier installations have deployment times of a little as 20 minutes. When stored

properly, the life expectancy of this product family is projected between 15-20 years.

4x stronger than nylon

Installation Types

In the FloodBarrier line of flexible systems, there are Portal FlexBarrier, Side FlexBarrier,

Pull-up FlexBarrier, Roll-Down FlexBarrier, Free standing FlexBarrier and Grate FlexBarrier

Flexible Membrane Systems to protect the most challenging project designs.

Independent Laboratory tested to ANSI 2510 guidelines.

Flex Barrier Types currently installed:

Portal FlexBarrier is a high-performance product for complete perimeter tunnel closures.

Side FlexBarrier is a flex product for openings up to almost any practical length using stanchion posts to ensure

span support, installations to date up to 10 ft water height.

Pull-up FlexBarrier is an in-ground stored product that also extends to almost any practical length using a stanchion

posts and height are dependent on the structure to be fitted.

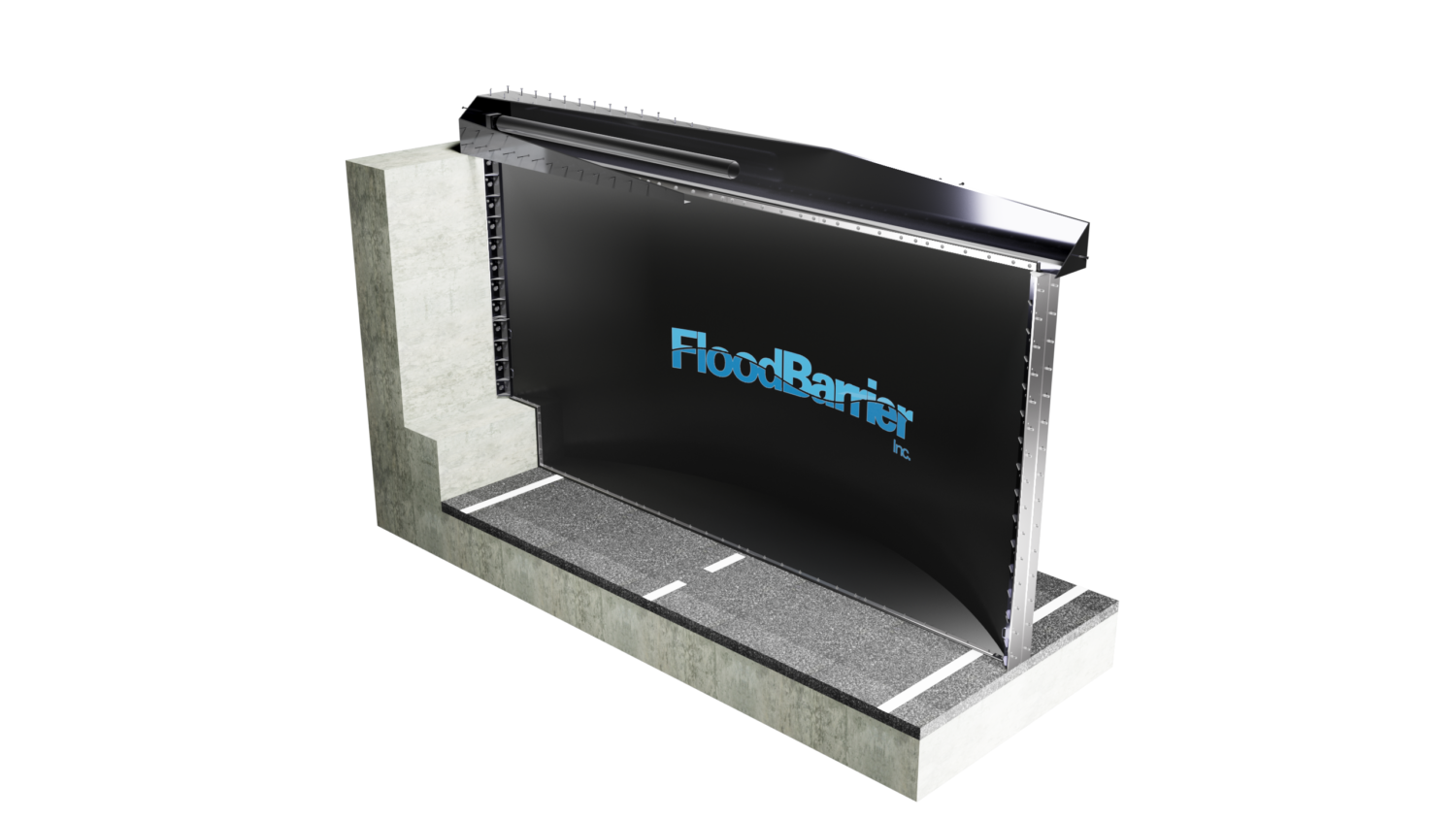

Roll-Down FlexBarrier is an overhead rolled product commonly utilized in garage entrances or similarly designed

openings up to approximately 20’ in height and a water height somewhat below that.

Free Standing FlexBarrier is a free-standing barrier when deployed. This design may be used to create dry “islands.”

To Life Safety egress or to wrap around a free-standing utility or other infrastructure-related component.

Grate FlexBarrier is a horizontally deployed barrier preventing water ingress in ventilation applications.

Standards:

All products comply with unique project specifications and where applicable:

ASCE 24-05, Flood Resistant Design and Construction; ASCE 7-05 or 7-10, Minimum Design

Loads for Buildings and Other Structures; AA Aluminum Design Manual 2010; ADM-1-00,

Aluminum Design Manual; AA SAS 30 Specifications for Aluminum Structures; AISC Design

Guide 27-15, Structural Stainless Steel; AISC 303-05, Code of Standard Practice for Steel

Buildings and Bridges; AISC 360-05, Specification for structural steel buildings; AWS

Structural Welding Code D1, D1.2, D1.3, D1.6; ASCE 55-16, Tensile Membrane Structures;

FEMA Bulletins 3-93, #102 & #114; National Flood Insurance Program (NFIP); 1986 Florida

Building Code 2001 for High Velocity Wind; Building Code of New York State